Badboymelvin

AH fanatic

- Joined

- Dec 5, 2013

- Messages

- 544

- Reaction score

- 2,214

- Location

- Geelong, Victoria, Australia

- Media

- 25

- Articles

- 2

Hey guy's

I posted a little while ago that I have purchased a rifle from NT Firearms Gove and l thought I'd give an update.

To refresh everyone's memory the rifle is a Zastava M70 chambered in 425 Express.

The rifle was posted several weeks ago but l still haven't got it! It's still sitting at my LGS awaiting a permit. You see the Licensing and Regulation Division haven't heard of a 425 Express before and it's not on their list, so they have to do it manually and they are taking their sweet time about it...

So while l'm waiting for the rifle l thought l'd use my time wisely.

While l was waiting for the rifle, a package from NT Firearms Gove arrived. And inside was this...

Awesome. 100 cases and some dies. Now these dies weren't mine, mine were still coming so Farmboy lent me his until mine arrived - which is an awesome gesture. Thanks mate.

The cases were unformed virgin brass and looked like this...

But what made them really cool was this...

This was all organised by NT Firearms Gove.

Now l had 100 cases to form.

First step was running one through the FLS die. I removed the expanding rod from the die and then ran a well lubed case into the die. I did this in steps - not one pass.

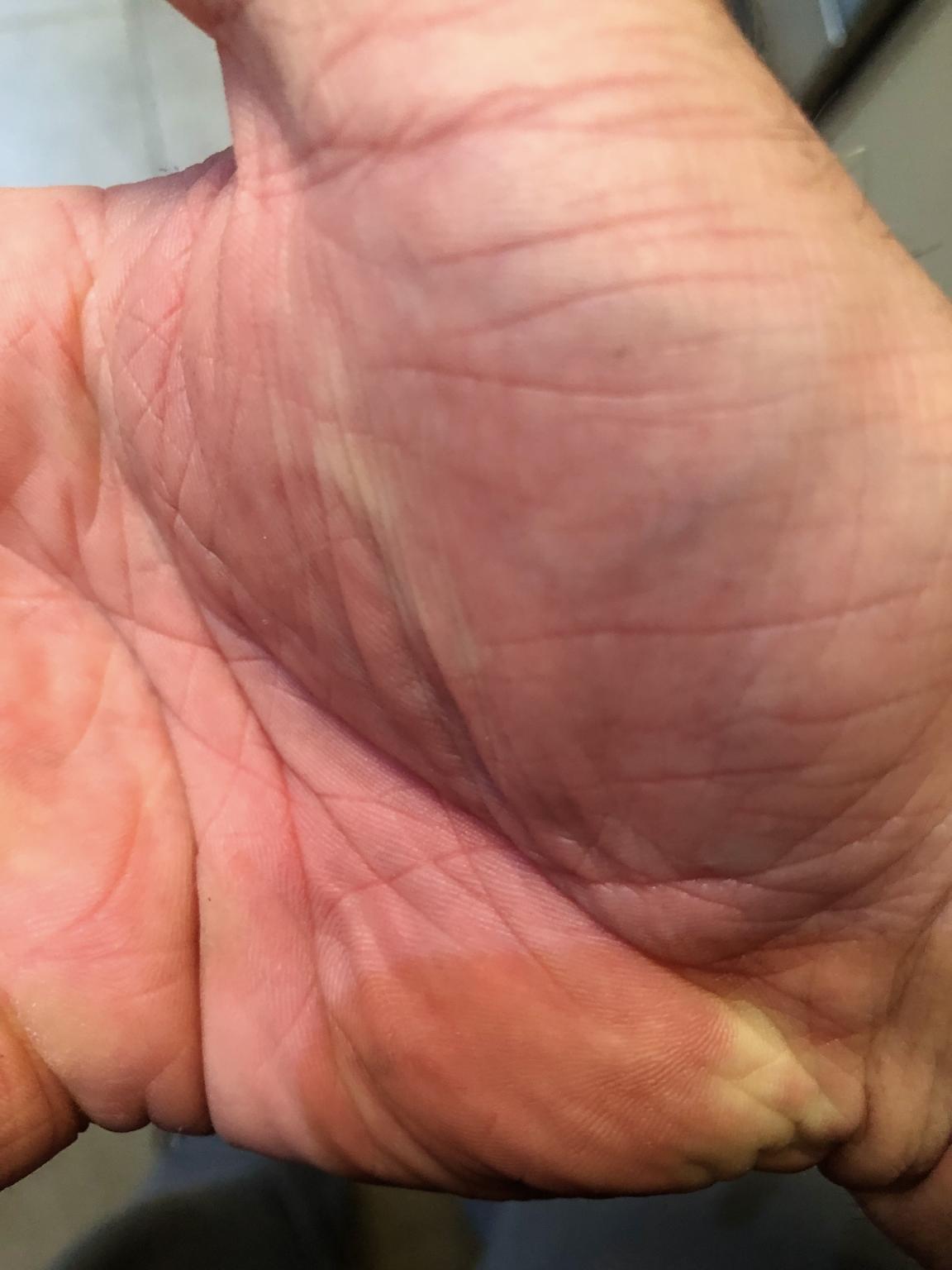

The brass then looked like this...

So l then sat down and formed 50 cases. The funny thing about this was that l had just moved house and haven't yet set up a reloading bench, so l formed all these cases using my Lee hand press. What a workout that was!

I then had to trim the cases. To make this step easier, l went to a mate who has a workshop and we machined up this case length gauge that screws into my cutter. It looks like this...

So the process I use is to trim the cases roughly so they are about 1mm too long, then use the case length gauge to trim them precisely. To roughly trim them, at first l used a small pipe cutter but l had mixed success with that method so l now use a belt sander to roughly trim, followed by the case length gauge.

Here's what the case looks like trimmed...

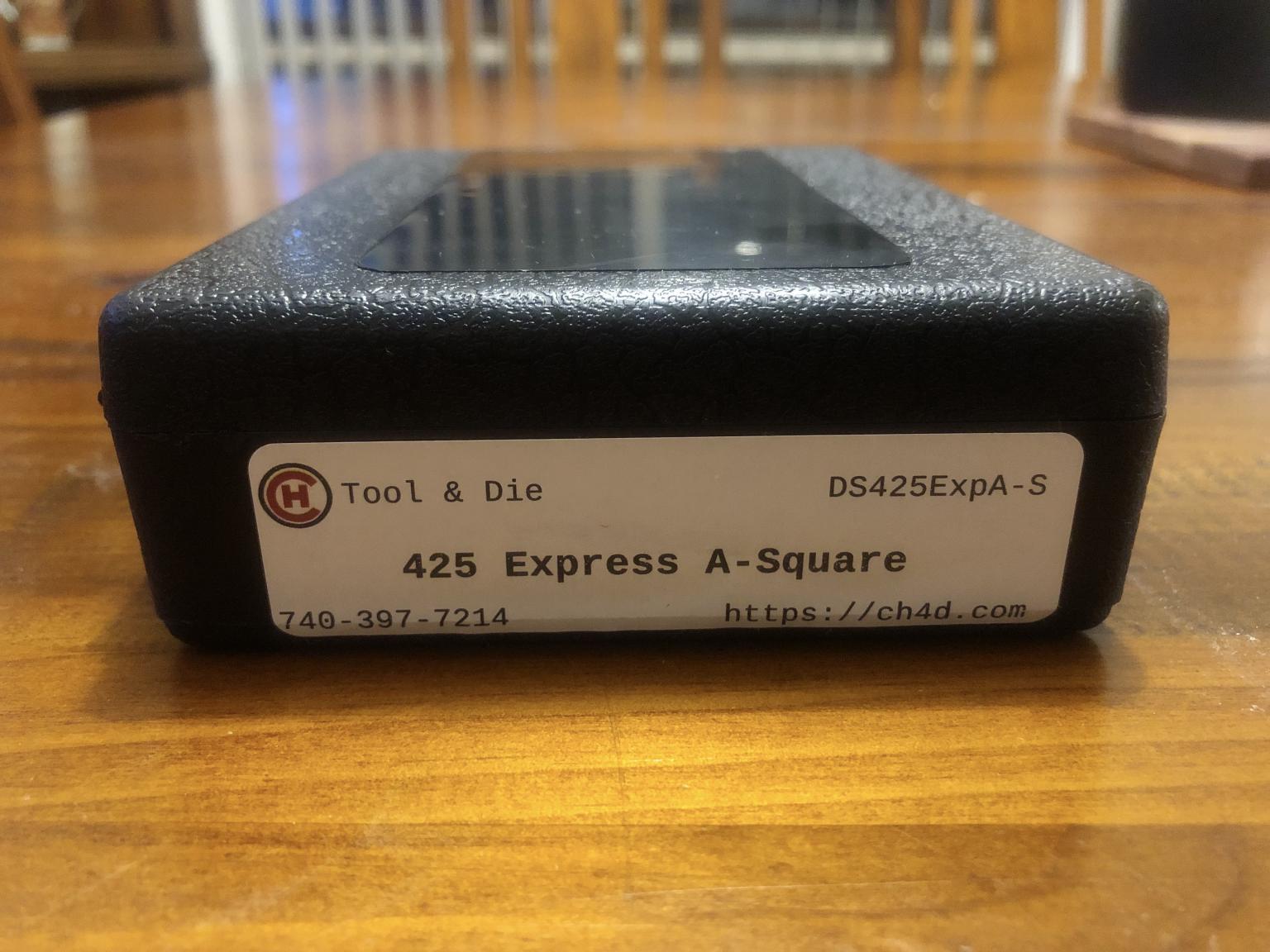

While all this was happening l received another package from NT Firearms Gove. Inside was this... awesome...

So that's where I'm up to guys. I have the cases formed and trimmed and I'm going to call NT Firearms Gove to chat about load data.

So next thing on the shopping list will be projectiles, powder and primers - so keep posted as l'm starting to get to the exciting part!

To be continued...

Russ

I posted a little while ago that I have purchased a rifle from NT Firearms Gove and l thought I'd give an update.

To refresh everyone's memory the rifle is a Zastava M70 chambered in 425 Express.

The rifle was posted several weeks ago but l still haven't got it! It's still sitting at my LGS awaiting a permit. You see the Licensing and Regulation Division haven't heard of a 425 Express before and it's not on their list, so they have to do it manually and they are taking their sweet time about it...

So while l'm waiting for the rifle l thought l'd use my time wisely.

While l was waiting for the rifle, a package from NT Firearms Gove arrived. And inside was this...

Awesome. 100 cases and some dies. Now these dies weren't mine, mine were still coming so Farmboy lent me his until mine arrived - which is an awesome gesture. Thanks mate.

The cases were unformed virgin brass and looked like this...

But what made them really cool was this...

This was all organised by NT Firearms Gove.

Now l had 100 cases to form.

First step was running one through the FLS die. I removed the expanding rod from the die and then ran a well lubed case into the die. I did this in steps - not one pass.

The brass then looked like this...

So l then sat down and formed 50 cases. The funny thing about this was that l had just moved house and haven't yet set up a reloading bench, so l formed all these cases using my Lee hand press. What a workout that was!

I then had to trim the cases. To make this step easier, l went to a mate who has a workshop and we machined up this case length gauge that screws into my cutter. It looks like this...

So the process I use is to trim the cases roughly so they are about 1mm too long, then use the case length gauge to trim them precisely. To roughly trim them, at first l used a small pipe cutter but l had mixed success with that method so l now use a belt sander to roughly trim, followed by the case length gauge.

Here's what the case looks like trimmed...

While all this was happening l received another package from NT Firearms Gove. Inside was this... awesome...

So that's where I'm up to guys. I have the cases formed and trimmed and I'm going to call NT Firearms Gove to chat about load data.

So next thing on the shopping list will be projectiles, powder and primers - so keep posted as l'm starting to get to the exciting part!

To be continued...

Russ

Attachments

Last edited by a moderator: