fourfive8

AH ambassador

- Joined

- Apr 27, 2017

- Messages

- 5,301

- Reaction score

- 12,590

- Location

- Western Slope CO, Mindanao RoP

- Media

- 265

- Hunted

- USA, South Africa, Mozambique, Zimbabwe, Zambia, Botswana

Currently I have no "target" rifles- the herd has been thinned to serious hunting rifles only. Not even a rattle battle in the closet- they went down the sale chute long ago. My recreational and hobby shooting/loading now with high-power smokeless is all about 100% reliable hunting ammo with bullets I know will work and are acceptably accurate. My other shooting passion is black powder original muzzleloaders- but that's for a different thread.

My accuracy standard for hunting ammo/rifles is about 1" or less @ 100 yds across the board. I shoot once in a while at 300 yards but will not shoot at animals any farther than that even though a couple of my rifles are fully capable of it. Simple- animal sniping for bragging rights has become a trendy thing that I will not participate in. At one time I had a couple of 308s, a 6 and a 6.5 that were scary accurate. Actually it got old and tiring trying to squeeze the last .01-.05”

of accuracy out of them each time out. I don't miss them nor the challenge of that game... the education was not cheap but hopefully I learned a few things along the way.

Using those lessons over the past 50 years of reloading and shooting and putting rifles together, I feel comfortable in the field for any game at my chosen time and distance and condition to shoot. I also have come to realize that if a rifle is basically accurate, you should be able to tell pretty quickly. Fighting a basically inaccurate rifle can be frustrating and wasteful of time. There is no magic load for those rifles. Always best to recognize that and nip that issue in the bud early on!!!

I enjoy working up loads, not for velocity but for the goal of 100% reliably and cleanly killing big game. All my rifles are either bedded in quality synthetic stocks or pillar and full length bedded in wood. Nothing fancy- but 100 % practical and functional with the wood being factory standard grade walnut by Winchester and the synthetics by HS Precision. The barrels are mixture of factory, Krieger and Lilja. Some rifles are factory and some are put together with good barrels and custom chamber reamers. The put together actions have been trued as much as can easily be done with a CRF Winchester or Mauser design.

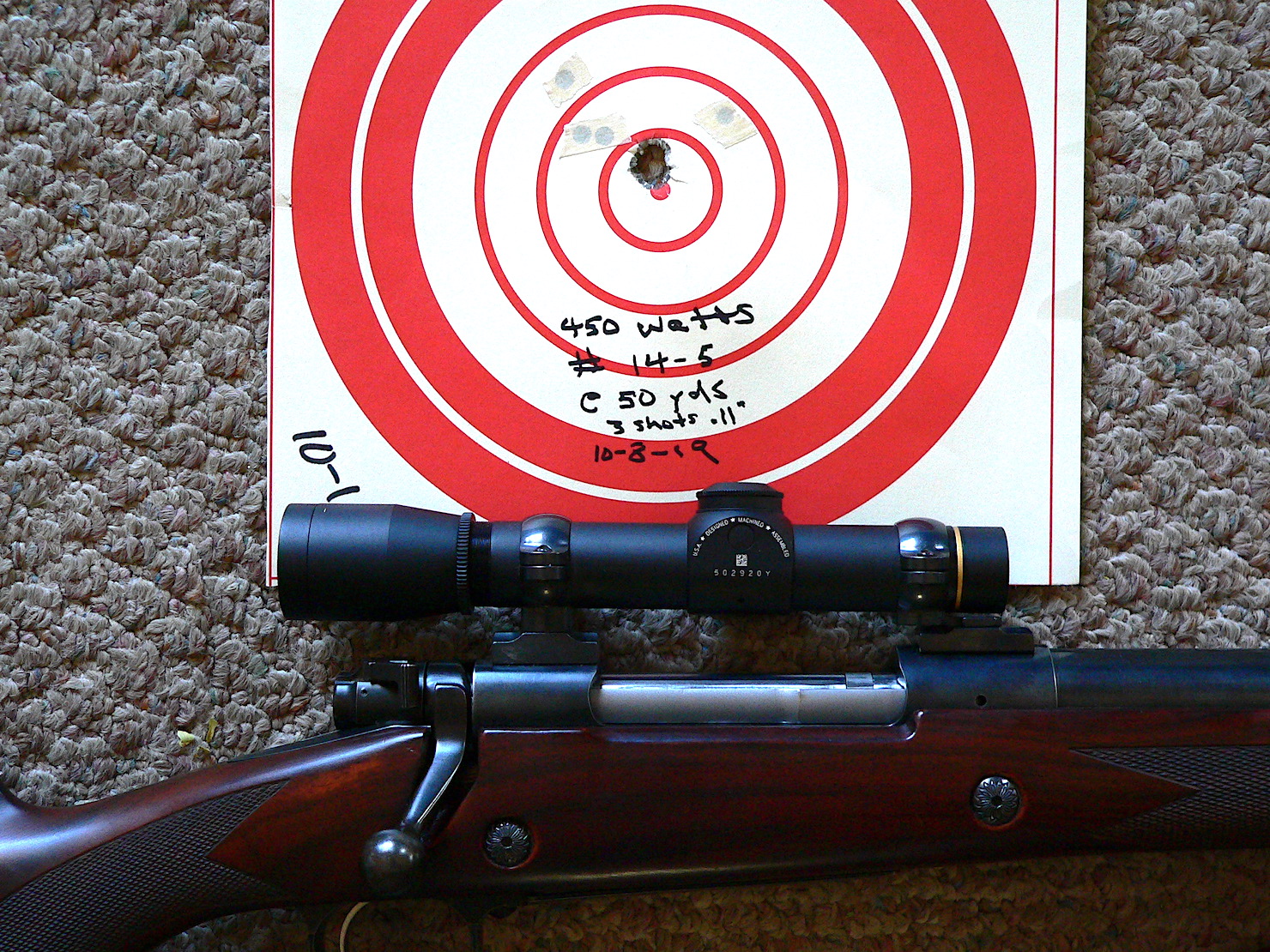

Here's an example of targets from one of them- Pic of two targets shot with 450 Watts @ 50 yds off bench with a couple of different loads. Hunting type ammo, Lee FCD crimped. FXII Ultralight 2.5x20 Leupold scope. Shot 4 1/2 years apart. One target with TSX the other with GS Custom Flat Nose Solid. The three most accurate, premium big game bullets I've shot in all rifles are all banded monolithic copper... the TSX, the North Fork Flat Point and Cup Point Solids and the GS Flat Nose Solid. Rifle and scope were untouched in the 4 1/2 years between shoots. Obviously more accurate than required, but fun to do once in a while with a big gun My 375 HH and 416 Rem Mags in Win 70s will almost do this well. Matter of fact my 375 HH shot a hunting load group last week of about .6" at 100 yds. My 270 Win and 338-06 both in Win 70 usually will.

My 375 HH and 416 Rem Mags in Win 70s will almost do this well. Matter of fact my 375 HH shot a hunting load group last week of about .6" at 100 yds. My 270 Win and 338-06 both in Win 70 usually will.

My accuracy standard for hunting ammo/rifles is about 1" or less @ 100 yds across the board. I shoot once in a while at 300 yards but will not shoot at animals any farther than that even though a couple of my rifles are fully capable of it. Simple- animal sniping for bragging rights has become a trendy thing that I will not participate in. At one time I had a couple of 308s, a 6 and a 6.5 that were scary accurate. Actually it got old and tiring trying to squeeze the last .01-.05”

of accuracy out of them each time out. I don't miss them nor the challenge of that game... the education was not cheap but hopefully I learned a few things along the way.

Using those lessons over the past 50 years of reloading and shooting and putting rifles together, I feel comfortable in the field for any game at my chosen time and distance and condition to shoot. I also have come to realize that if a rifle is basically accurate, you should be able to tell pretty quickly. Fighting a basically inaccurate rifle can be frustrating and wasteful of time. There is no magic load for those rifles. Always best to recognize that and nip that issue in the bud early on!!!

I enjoy working up loads, not for velocity but for the goal of 100% reliably and cleanly killing big game. All my rifles are either bedded in quality synthetic stocks or pillar and full length bedded in wood. Nothing fancy- but 100 % practical and functional with the wood being factory standard grade walnut by Winchester and the synthetics by HS Precision. The barrels are mixture of factory, Krieger and Lilja. Some rifles are factory and some are put together with good barrels and custom chamber reamers. The put together actions have been trued as much as can easily be done with a CRF Winchester or Mauser design.

Here's an example of targets from one of them- Pic of two targets shot with 450 Watts @ 50 yds off bench with a couple of different loads. Hunting type ammo, Lee FCD crimped. FXII Ultralight 2.5x20 Leupold scope. Shot 4 1/2 years apart. One target with TSX the other with GS Custom Flat Nose Solid. The three most accurate, premium big game bullets I've shot in all rifles are all banded monolithic copper... the TSX, the North Fork Flat Point and Cup Point Solids and the GS Flat Nose Solid. Rifle and scope were untouched in the 4 1/2 years between shoots. Obviously more accurate than required, but fun to do once in a while with a big gun

My 375 HH and 416 Rem Mags in Win 70s will almost do this well. Matter of fact my 375 HH shot a hunting load group last week of about .6" at 100 yds. My 270 Win and 338-06 both in Win 70 usually will.

My 375 HH and 416 Rem Mags in Win 70s will almost do this well. Matter of fact my 375 HH shot a hunting load group last week of about .6" at 100 yds. My 270 Win and 338-06 both in Win 70 usually will.

Last edited: