You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is Annealing important for hunting loads?

- Thread starter Pheroze

- Start date

JimP

AH ambassador

- Joined

- Dec 14, 2014

- Messages

- 5,399

- Reaction score

- 13,046

- Location

- Gypsum, Co

- Media

- 65

- Member of

- NRA, RMEF

- Hunted

- US (Utah, Arizona, Idaho, Colorado, Nevada. Canada (British Colombia), South Africa (Eastern Cape)

It helps with the life of the brass.

If you don't shoot and reload the brass a lot then the extra time to do it might not be worth it to you. But if you shoot a lot and want to lengthen the life of the brass then it is worth it

If you don't shoot and reload the brass a lot then the extra time to do it might not be worth it to you. But if you shoot a lot and want to lengthen the life of the brass then it is worth it

tedthorn

AH enthusiast

- Joined

- Jul 2, 2014

- Messages

- 480

- Reaction score

- 632

- Location

- South East Missouri

- Media

- 32

- Hunted

- Eastern Cape of South Africa

I have been reading a lot about annealing. Is this mainly for competitors or should hunters anneal their brass too?

It is most important to extend brass life

sestoppelman

AH ambassador

The above is what I keep reading, but I never have bothered, too far into the weeds for me and I get good case life regardless. Brass is like powder and primers, its a consumable. It lasts longer than the others but you can anneal till the cows come home and it will still wear out.

Pheroze

AH ambassador

Thanks guys. I load a 308 Norma Mag which is not really easy to find. So might be just worth it to buy an anealing machine of some form. Although, they are not cheap and that can buy a bunch of brass.

sestoppelman

AH ambassador

I don't think most guys go to that expense to anneal, not really required, though perhaps more convenient.

I think most just heat the neck up with a torch and knock them over into water.

I think most just heat the neck up with a torch and knock them over into water.

Pheroze

AH ambassador

I was wondering that. I am sure youtube has something about thatI don't think most guys go to that expense to anneal, not really required, though perhaps more convenient.

I think most just heat the neck up with a torch and knock them over into water.

JimP

AH ambassador

- Joined

- Dec 14, 2014

- Messages

- 5,399

- Reaction score

- 13,046

- Location

- Gypsum, Co

- Media

- 65

- Member of

- NRA, RMEF

- Hunted

- US (Utah, Arizona, Idaho, Colorado, Nevada. Canada (British Colombia), South Africa (Eastern Cape)

I have a couple of plans for a home made annealing machine that you can put together with some parts from the hardware store. One does require a couple of motors from Ebay. Let me know if you would like them. One is a YouTube video and the other one is a video and plans.

I just used a cake pan and torch for years, but I still think about building one.

I just used a cake pan and torch for years, but I still think about building one.

Pheroze

AH ambassador

That sounds like it could be a fun project. Please do share those plans, thanks!I have a couple of plans for a home made annealing machine that you can put together with some parts from the hardware store. One does require a couple of motors from Ebay. Let me know if you would like them. One is a YouTube video and the other one is a video and plans.

I just used a cake pan and torch for years, but I still think about building one.

Still alive

AH enthusiast

You can use tempilaq to make sure your heating the case with the torch the same every time

Hunter4752001

AH elite

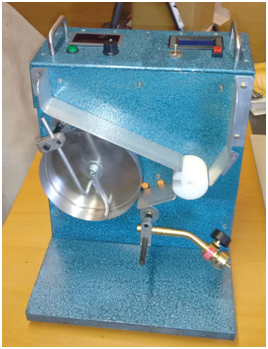

I built one earlier this year. Not terribly complex nor expensive.

The cases are stacked in the hopper. The white rotor feeds them down the ramp and into a rotating drum (a cut down cake tin) where the neck sticks out into the flame from the propane torch. Drum rotation is controlled by a speed controller thereby determining the time spent in the flame and hence the neck temperature. The drum has a slot in th side which causes the case to drop out after one rotation.

The cases are stacked in the hopper. The white rotor feeds them down the ramp and into a rotating drum (a cut down cake tin) where the neck sticks out into the flame from the propane torch. Drum rotation is controlled by a speed controller thereby determining the time spent in the flame and hence the neck temperature. The drum has a slot in th side which causes the case to drop out after one rotation.

JimP

AH ambassador

- Joined

- Dec 14, 2014

- Messages

- 5,399

- Reaction score

- 13,046

- Location

- Gypsum, Co

- Media

- 65

- Member of

- NRA, RMEF

- Hunted

- US (Utah, Arizona, Idaho, Colorado, Nevada. Canada (British Colombia), South Africa (Eastern Cape)

gillettehunter

AH ambassador

Try googling salt bath annealing. I'd link some info here, but AH doesn't allow that. Can get the materials for around $120. I have moved from the torch and socket approach to this.

Bruce

Bruce

Cleveland48

AH enthusiast

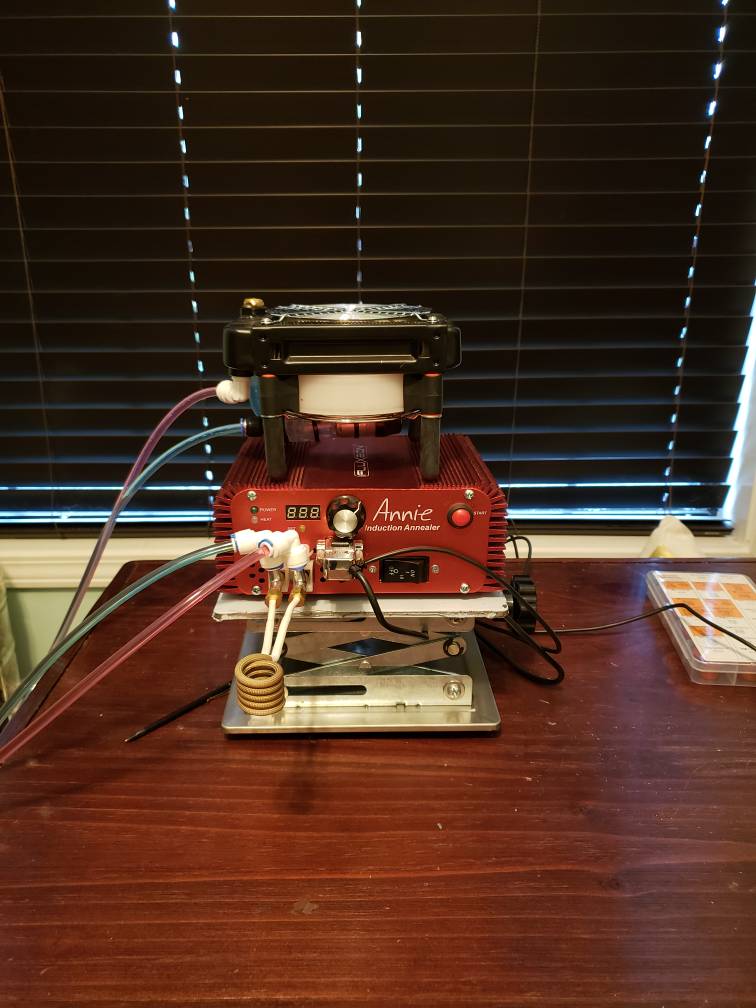

Here is my annealing setup. Annie induction annealer with the water cooled mini radiator. Has 100 % duty cycle so it anneals as fast as you can put a case in it. With all the calibers I load for, my anneal times vary from 1.3 to 2.7 seconds per case. Depending on the brass. I shoot alot, so I anneal every firing since my annealing is so much faster now. That way I dont have to keep up how many times a case has been fired, and remember when i anneal it. But you do not need such equipment. I've used the candle method and just the torch method using my fingers, and they all work. If your only doing 50 pcs of brass or less at a time then there is really no need to drop $1,000 on a super fancy annealer.

If you are a low volume annealer the method described in Any Shot You Want works by holding base in fingers and rotating neck and shoulders in the flame. When too hot to hold drop in water(not necessary) or drop in metal pan to cool

Pheroze

AH ambassador

If you are a low volume annealer the method described in Any Shot You Want works by holding base in fingers and rotating neck and shoulders in the flame. When too hot to hold drop in water(not necessary) or drop in metal pan to cool

Now that seems low budget for sure!

Cleveland48

AH enthusiast

I used that method for a long while with a candle, or torch. And it does work very well for low volume.If you are a low volume annealer the method described in Any Shot You Want works by holding base in fingers and rotating neck and shoulders in the flame. When too hot to hold drop in water(not necessary) or drop in metal pan to cool

Members online

- Andrew62

- Chadc

- Levubu

- Camdog

- mark-hunter

- JHT

- Hunting Hitman

- Ndczerwinski

- MontanaPat

- CM McKenzie

- Atticus

- SFRanger7GP

- Rafiki

- Boyd Brooks

- Mort Hill

- Bwgunslinger

- thoma018

- Tex .416

- Francois R

- AZDAVE

- steve white

- toxic111

- Wishfulthinker580

- mdwest

- Nlee70

- Tyguy

- Kootenay Hunter

- RLD

- PanhandlinPat

- slam8031

- jb1069

- EuroOptic

- Hannay

- Wade J VanGinkel

- Shako Badhan

- tblom

- SETH RINGER

- cajunchefray

- rafter3

- JimmyJack54

- HankBuck

- RR 314

- channelkat

- 303cknman

- Buckums

- TKessel

- light_weight

- Oil & Dirt

- 549

- pennsport

Total: 271,464 (members: 1,122, guests: 270,342)

Forum statistics

Latest profile posts

Happy birthday Tommy1005 we hope the year ahead is filled with alot of hunting!