deewayne2003

AH legend

With Lee being out of the custom die game for an undetermined amount of time; I am wondering if it would be possible to have a machine shop modify an existing .416 Rigby factory crimp die?

Can someone on the forum with machining experience tell me if I'm onto something and how difficult/expensive would it be to modify this die to .404J?

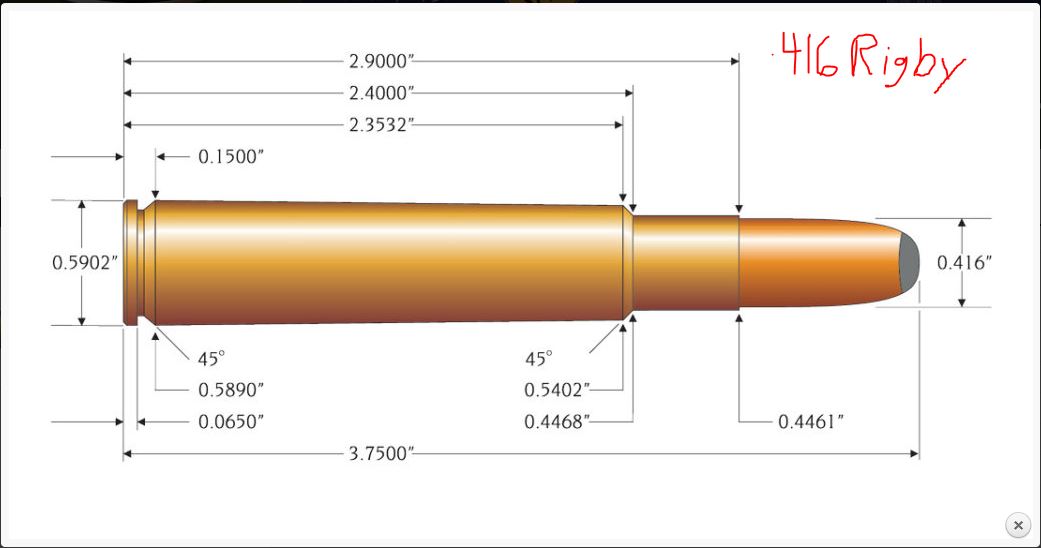

As I see it the .416Rigby is larger in every dimension....oddly enough except for the projectile & neck.

So would it be as simple as ....

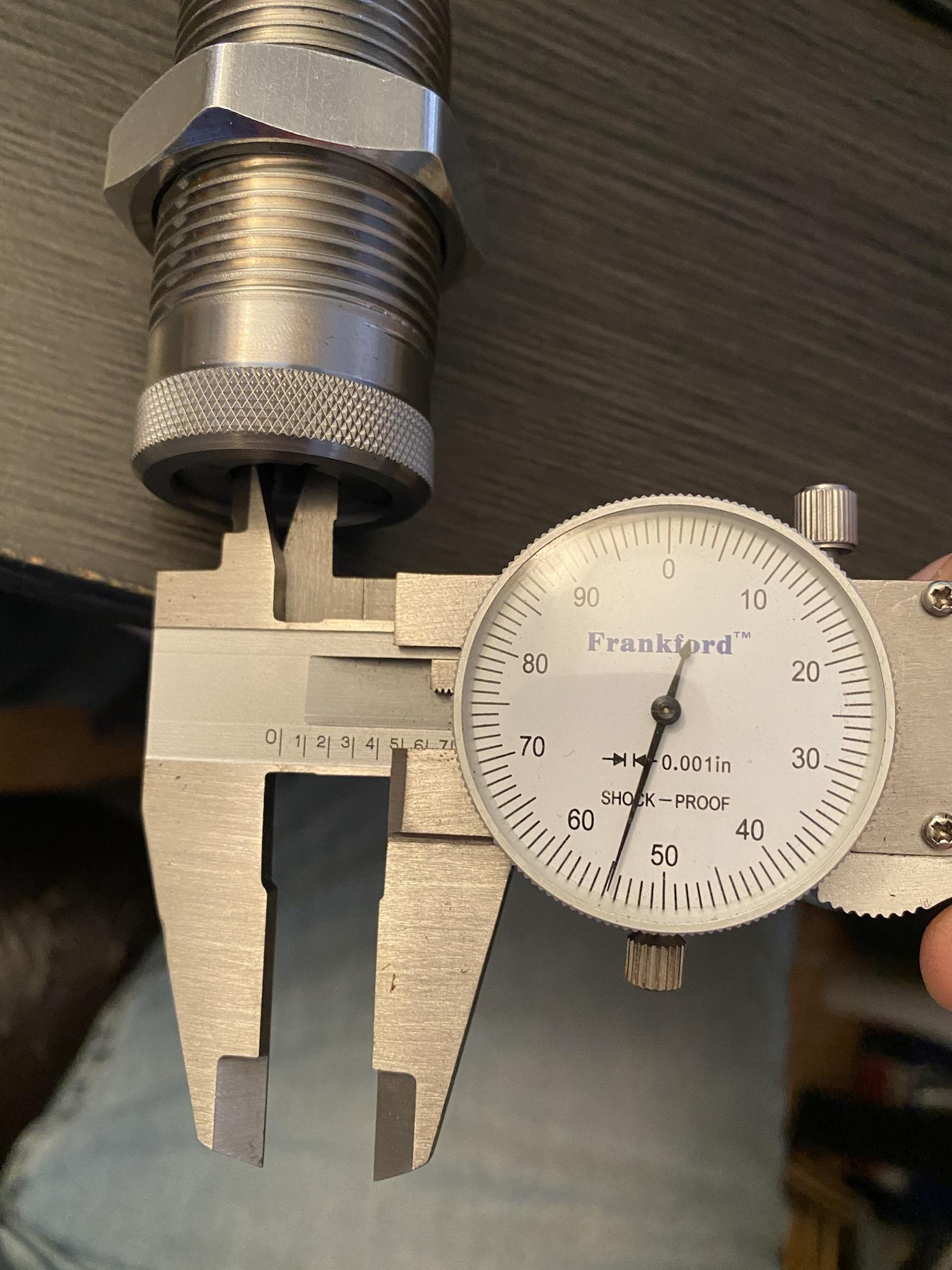

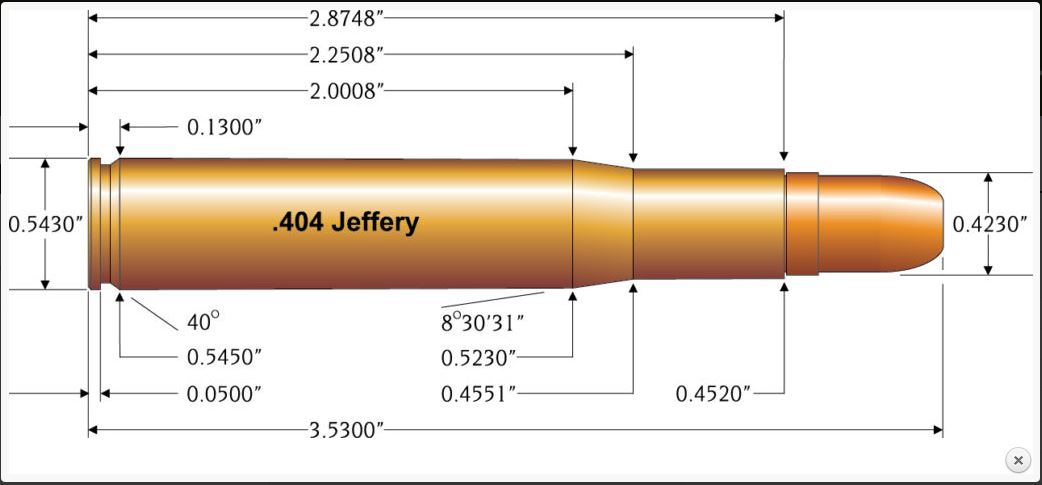

Shortening the die body or machining a spacer to make the difference between 2.8748 & 2.9000 (.0252"); and then opening up the 'crimp petals' .007" to accept the larger projectile?

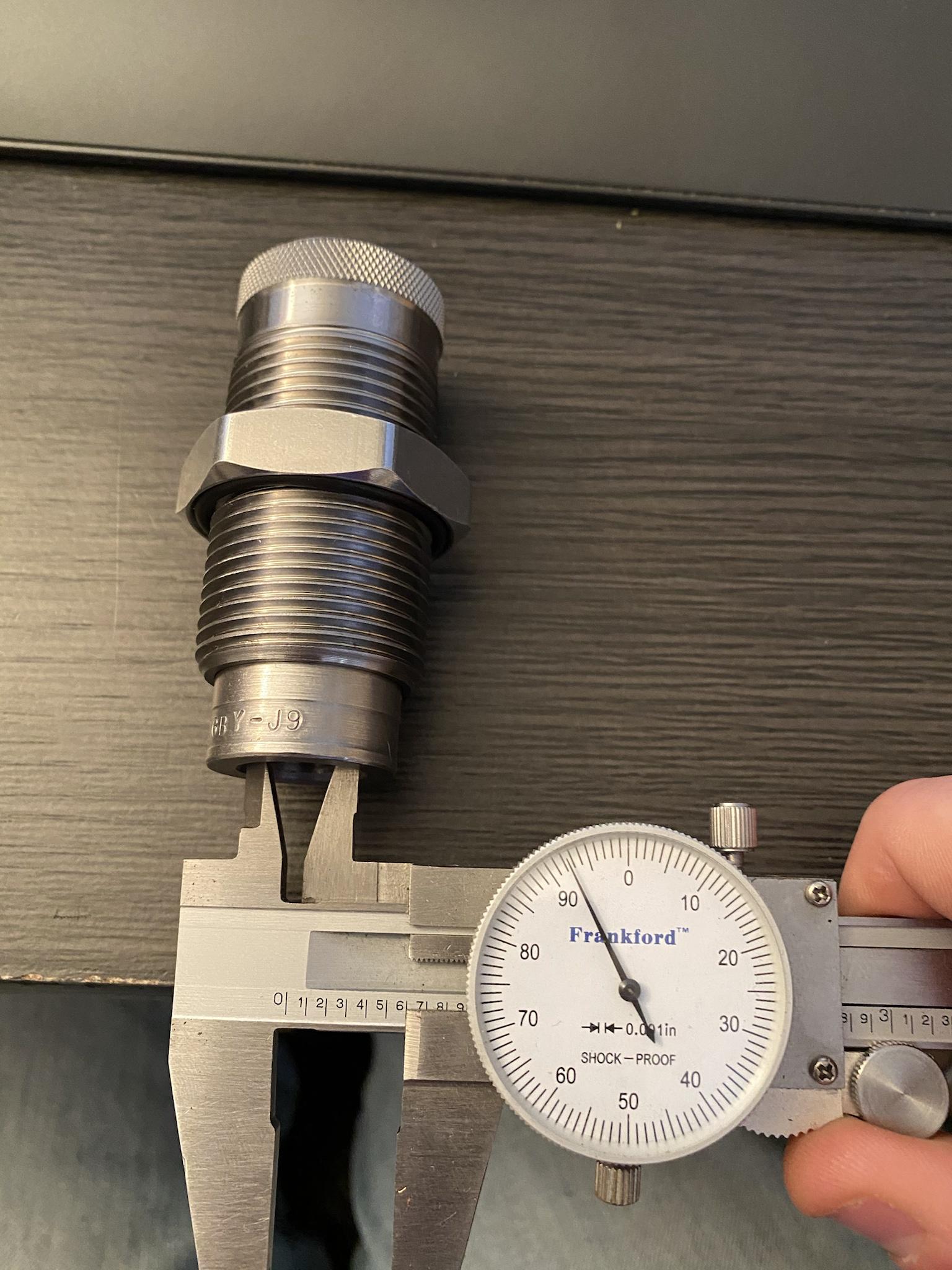

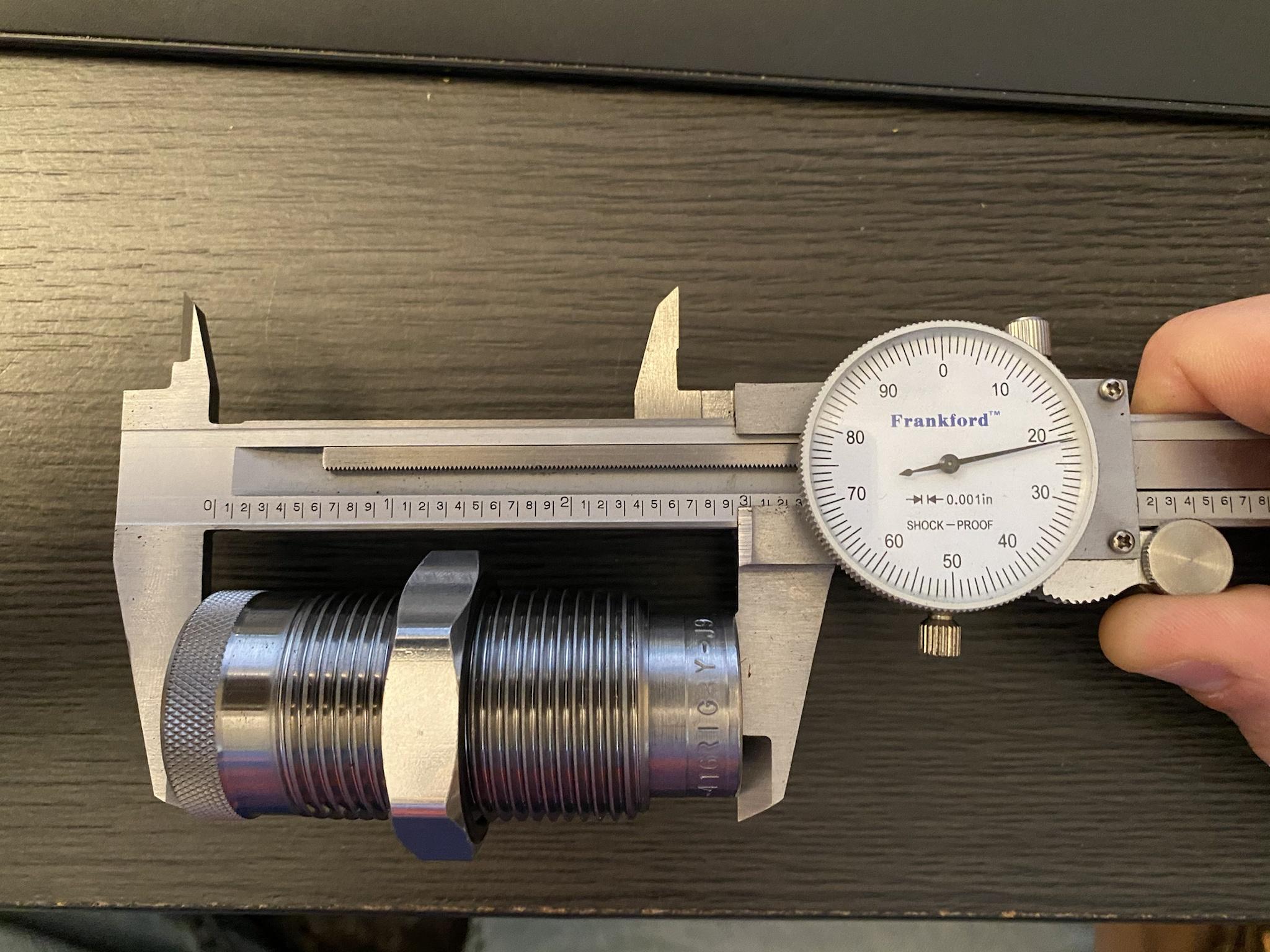

This is a Lee Factory Crimp die in .416 Rigby

.416 Rigby

.404J

P.S. - I'll be impressed if we can keep this thread on track and answer the question at hand without someone throwing in their opinion on crimping merits or how they use their (insert opinion/method) instead of answering the question.

Can someone on the forum with machining experience tell me if I'm onto something and how difficult/expensive would it be to modify this die to .404J?

As I see it the .416Rigby is larger in every dimension....oddly enough except for the projectile & neck.

So would it be as simple as ....

Shortening the die body or machining a spacer to make the difference between 2.8748 & 2.9000 (.0252"); and then opening up the 'crimp petals' .007" to accept the larger projectile?

This is a Lee Factory Crimp die in .416 Rigby

.416 Rigby

.404J

P.S. - I'll be impressed if we can keep this thread on track and answer the question at hand without someone throwing in their opinion on crimping merits or how they use their (insert opinion/method) instead of answering the question.

Last edited by a moderator: