Nhoro

AH elite

- Joined

- Sep 16, 2014

- Messages

- 1,137

- Reaction score

- 2,220

- Location

- Harare,Zimbabwe

- Media

- 29

- Member of

- Cleveland Gun Club

- Hunted

- Zimbabwe

I wanted to put down my thoughts,opinions and actions that I used to tune a CZ 550 in 458 win mag, from what I understand, that caliber is particularly difficult being short and fat. I searched the internet and there was not much to be found. Duane Wiebe has posted a brief process on another forum and Von Gruff posted Proper Magazine Layout on africahunting forum and these were most helpful but don’t really tell you why you do something or what it affects. I found that as you feed the round, things are more complex than you first think and changing one thing invariably changes another. For what it is worth, here are my thoughts, use them at your peril! Some of you may have more experience than me and can add some bits that I got wrong or left out.

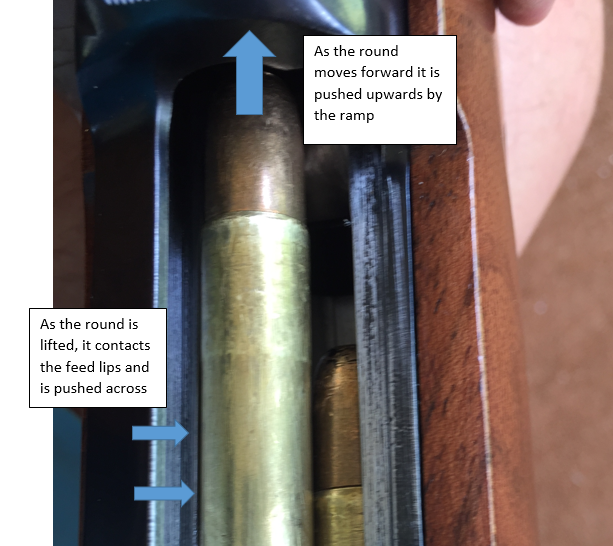

The bullet riding up the ramp initiates the process the feed action so I started there. As it lifts the front of the round, the cartridge case contacts the feed lips/side rails and pushes the round away from the side of the magazine and towards the center to align with the chamber. I expected the ramp to funnel the bullet into the chamber but found the cone shape does little for the left/right movement. See the diagram below for more clarity.

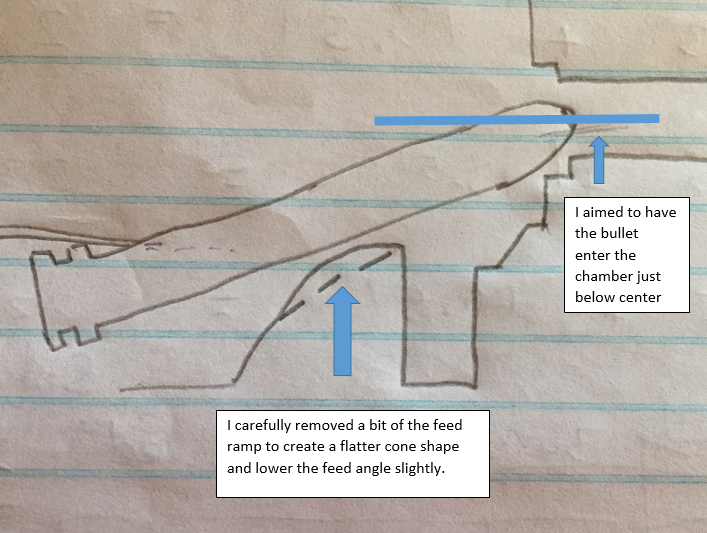

I carefully removed a bit of the feed ramp to create a flatter cone shape and lower the feed angle slightly.

If you alter the angle of the feed ramp by making the angle shallower, the feeding round will move away from the rail later in the feeding cycle. In addition, if you remove the feed rail from where it touches the case as you feed, the round will also be pushed away from the rail less and later in the feeding cycle. I tried to keep the round feeding to the center of the chamber. I removed material from the feeding ramp to aim the cartridge just below center of the chamber. I figured that I was using dummy rounds with the shortest bullet or head(480 gr hornady dgs) Other heads would be monolithics or 500 gr solids and longer so I left room.

I sloped the feed ramp to give a shallow angle of entry into the chamber but beware, the back of the feed ramp is the locking lug surface. A shallow angle of entry means that the camming of the bullet that slides it up the bolt face and out of the feed lips is easier. The bullet should enter the chamber just before the case leaves the magazine feed lips.After removing a bit of the feed ramp, I marked the feed lips with a marker where they pushed the case across too much and removed them with a file. I used small slips of paper to help, sliding the paper between the feed lip and cartridge to see where it was touching. The main problem I had was just as the bullet gets close to the chamber mouth, it is pushed wide and catches on the chamber mouth even after the feed lips are no longer touching the cartridge, apparently it is a common problem with CZ, especially when feeding from the left side. At this point I found that if I pushed the cartridge straighter, to line up with the chamber, it sprung back. It must be to do with the magazine and magazine spring because that is the only sprung part that is involved. I wracked my brains for a while and remembered Von Gruff’s post about Proper Magazine Layout. In that article, it states that if the magazine box is too narrow, it will cause crossover. That was what I was experiencing so I measured the box in the critical area where the bullet entered the chamber and it is 2 mm narrower than suggested by the formula in the article. So with much trepidation, I started removing material from the inside of the magazine box on the left and right. As I did so, the bullet slowly moved more central each time I tried it. I removed about ¼ mm on the left side. As the magazine box was widened, the cartridges stack more widely and this changes the tension on the bullet and the angles that are applied. Below is a photo with a matchbox to indicate the area and cover up irrelevant parts. The arrow indicates the width of the box.

I used the rim diameter + diameter of the bottom round at that point to calculate proper width of 24 mm. I stopped removing material at 23 mm or there about because the round no longer sprung back and chambered every time for 100 + tests. What is interesting is that the article said that Mauser relieved his magazine boxes in the middle to reduce friction but I think that it may have been to solve this very problem. As the rim slides down, it is much wider than the cartridge and so needs about 1 mm extra width just as it reaches the chamber. The 458 win mag seems to be a perfect storm where a Lott will probably be fine because it is longer and has less steep angles as it feeds. Much thanks to Von Gruff and TokkieM for their answers to my Pm's

I used the rim diameter + diameter of the bottom round at that point to calculate proper width of 24 mm. I stopped removing material at 23 mm or there about because the round no longer sprung back and chambered every time for 100 + tests. What is interesting is that the article said that Mauser relieved his magazine boxes in the middle to reduce friction but I think that it may have been to solve this very problem. As the rim slides down, it is much wider than the cartridge and so needs about 1 mm extra width just as it reaches the chamber. The 458 win mag seems to be a perfect storm where a Lott will probably be fine because it is longer and has less steep angles as it feeds. Much thanks to Von Gruff and TokkieM for their answers to my Pm's

The bullet riding up the ramp initiates the process the feed action so I started there. As it lifts the front of the round, the cartridge case contacts the feed lips/side rails and pushes the round away from the side of the magazine and towards the center to align with the chamber. I expected the ramp to funnel the bullet into the chamber but found the cone shape does little for the left/right movement. See the diagram below for more clarity.

I carefully removed a bit of the feed ramp to create a flatter cone shape and lower the feed angle slightly.

If you alter the angle of the feed ramp by making the angle shallower, the feeding round will move away from the rail later in the feeding cycle. In addition, if you remove the feed rail from where it touches the case as you feed, the round will also be pushed away from the rail less and later in the feeding cycle. I tried to keep the round feeding to the center of the chamber. I removed material from the feeding ramp to aim the cartridge just below center of the chamber. I figured that I was using dummy rounds with the shortest bullet or head(480 gr hornady dgs) Other heads would be monolithics or 500 gr solids and longer so I left room.

I sloped the feed ramp to give a shallow angle of entry into the chamber but beware, the back of the feed ramp is the locking lug surface. A shallow angle of entry means that the camming of the bullet that slides it up the bolt face and out of the feed lips is easier. The bullet should enter the chamber just before the case leaves the magazine feed lips.After removing a bit of the feed ramp, I marked the feed lips with a marker where they pushed the case across too much and removed them with a file. I used small slips of paper to help, sliding the paper between the feed lip and cartridge to see where it was touching. The main problem I had was just as the bullet gets close to the chamber mouth, it is pushed wide and catches on the chamber mouth even after the feed lips are no longer touching the cartridge, apparently it is a common problem with CZ, especially when feeding from the left side. At this point I found that if I pushed the cartridge straighter, to line up with the chamber, it sprung back. It must be to do with the magazine and magazine spring because that is the only sprung part that is involved. I wracked my brains for a while and remembered Von Gruff’s post about Proper Magazine Layout. In that article, it states that if the magazine box is too narrow, it will cause crossover. That was what I was experiencing so I measured the box in the critical area where the bullet entered the chamber and it is 2 mm narrower than suggested by the formula in the article. So with much trepidation, I started removing material from the inside of the magazine box on the left and right. As I did so, the bullet slowly moved more central each time I tried it. I removed about ¼ mm on the left side. As the magazine box was widened, the cartridges stack more widely and this changes the tension on the bullet and the angles that are applied. Below is a photo with a matchbox to indicate the area and cover up irrelevant parts. The arrow indicates the width of the box.