USAN

AH fanatic

The 416 Rigby Norma load was the most consistent of the seven factory loads tested: Tested in the Ruger 77 Magnum, this load launched the 450-grain Woodleigh bullet at 2170 fps (muzzle velocity), precisely as advertised. Standard deviation for six shots was 7 fps. Both 3-shot groups were similar in size. I am quite sure that this gun and load will shoot smaller groups than I can manage using the recoil-discomfort minimizing rest system I employed for this testing. Most importantly, at 100 yards, this load shot only about 13Ž4-inches lower than the average for nineteentested handloads and six other tested factory loads, all loaded with 400- and 410-grain bullets.

The following article from Guns Magazine:

Dangerous-Game Good

The .416 Rigby In Ruger’s 77 Magnum Proves

Remarkably Consistent And Shoots To Point-Of-Aim

With Many Different Loads.

By M. L. McPherson

Earl Moore, whose lifetime dream had been to own a rifle chambered in .416 Rigby was thrilled to get one in the Ruger 77 Magnum. This is essentially a modern equivalent of Rigby’s original rifle. As the last rifle design upon which Bill Ruger had direct oversight, Moore figured this particular combination was a fine tribute to two great gun makers—Rigby and Ruger.

Then an acquaintance of Moore’s went to Africa, and, on the day he was to begin his hunt, discovered his carefully prepared .416 Rigby ammunition had vanished. To continue his hunt, he had to waste an entire day having his guide take him 200 miles to the nearest business with .416 ammo in stock. Forty rounds, $800!

Moore dreams of his own African safari. Therefore, he wondered how the zero of his .416 would vary with different factory loads. If he went to Africa and had to substitute ammunition, would it be necessary to waste valuable time rezeroing his gun, while absorbing the punishment of heavy recoil at the bench, messing up his schedule and perhaps the schedules of his guide and other hunters? Or, could he just go hunting and count on the replacement load to shoot close enough to his tested load so he could make well-centered hits on likely targets at reasonable distances?

He asked if I thought a comparison of zeros with various factory loads and factory-equivalent handloads was worthwhile. Having long realized Murphy’s Law was unreasonably optimistic, I agreed this was a worthwhile study.

So, we set out to obtain factory loads and components for testing. Hornady, Federal, and Norma were kind enough to provide factory ammunition. Alliant provided propellant. Federal provided primers. Hornady provided cases. Various bullet makers provided premium .416 Rigby bullets.

The rest set-up for days two and three allowed Mic to concentrate on

what matters—holding the gun the same way each time and squeezing the

trigger only when things were stable. Elevating the rests allowed Mic

to sit up more squarely behind the gun, which reduced the discomfort

of recoil. Consistent bag technique is key to shooting good groups.

Many who have not priced .416 Rigby ammunition ($7 per round) and components ($4 to 5 for a case, primer, propellant, and bullet) would be dumbfounded to discover just how expensive it is to shoot jacketed bullets from a Rigby. Moore figured out Alliant Reloder 22 was an ideal propellant choice and we knew the Federal 215 was the best primer available for such loads, so we did not have to do much load development work. Still, in this limited testing, we used up the better part of $1,000 worth of factory loads and components.

And, if we had had to purchase the seven boxes of factory ammunition, the 100 cases, the propellant and primers used, and one box of each tested bullet (some come in 10 or 20, and others as 50 per box), we would have exceeded $3,000. Therefore, the generous help of the manufacturers made this project possible.

Although Barnes monolithic bullets worked fine, we tested one other brand of bullet with innovative design features made of monolithic brass. It was worse than useless. By simply loading the magazine with rounds loaded with this bullet we proved that the inclusion of widely spaced circumferential grooves all along the bullet shank left too little of the shank in contact with the case neck for neck tension to hold the bullets in place against recoil. Firing the gun with a normal load generated enough recoil to drive the bullets in the rounds in the magazine back into the case significantly.

Therefore, I can’t too strongly caution against the use of any bullet lacking full or nearly full contact between case neck and bullet shank in this or any similar chambering. The one exception might be a combination where charge compression was sufficient to support the bullet against deeper seating, but how would you ever be completely certain? Better to just avoid such bullets.

This set-up helped minimize the discomfort of shooting more than 50

rounds of .416 Rigby ammunition in one morning. Several things helped:

the “X” bag binds the forearm, 5 pounds of lead shot at the back and,

elevating the gun enough so Mic can sit up behind it, instead of leaning

into it. A scope with ample eye relief is critical, and the Swarovski Z6

worked splendidly. Mic’s friend Rick Corbitt took this posed picture.

He wore shooting glasses for the test.

Details matter. On days two and three of range testing, Mic used his

conventional rests, but with both raised significantly. The tape

on the forearm was a guide to ensure he returned the rifle to the

same location in the front rest before each shot. Normally, for best

groups, Mic would have removed the front sling stud and positioned

the rest farther forward but that was not feasible here because

the stud secures the barrel band of the Ruger 77 Magnum.

Moore loaded all the tested handloads using unfired Hornady cases, Federal 215 primers, and Rl-22 propellant, a fine combination. His initial load development involved considerable preliminary shooting with several bullets. Because data does not exist for every bullet we tested, I used Moore’s preliminary test results to predict charges approximately duplicating factory-load velocity with all tested bullets. Moore loaded three such rounds with each bullet. With ammo in hand, we headed to the local range.

Standard loads fired in this rifle generate significantly more recoil than factory .458 Winchester Magnum loads fired in a gun of the same weight. Regardless of your sensitivity to recoil, bench testing this gun is a significant task. The first day of testing, just to get preliminary velocity data and to zero the scope, I fired 53 rounds. This was about all the fun I wanted to have in one day.

We did several things to reduce pain. I added a 5-pound bag of lead shot between the recoil pad and my shoulder. I have tested dozens of serious loads in the .45-70 Marlin and thereby proved that as long as I consistently position and hold the gun each time I squeeze the trigger, this technique has no effect on zero or accuracy. We also elevated the rests. This allowed me to sit up more squarely so my shoulder could more easily move with the recoil.

I also took aspirin each morning we shot. This is a good idea for me because it loosens my joints but it does promote bruising. I prefer the small amount of local bruising and less pain.

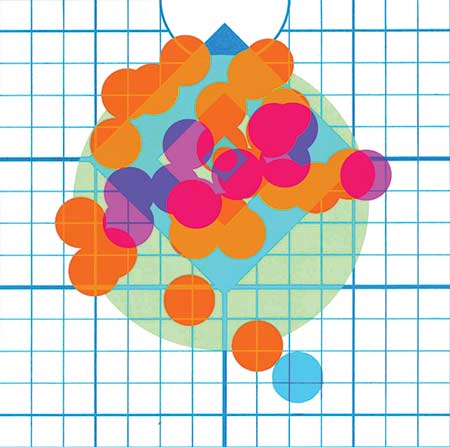

This represents what would have happened if Mic used the same point

of aim when firing all 41 shots during the second and third days

of testing (if the scope had been adjusted to center the weighted-average

impact). This is rather phenomenal, considering it represents 29

handload shots using 19 different bullet types plus the centers of

seven, 3-shot groups fired with six factory loads. Excepting the

Norma load, which uses a significantly heavier bullet, these centers

fell inside a 2-¼-inch circle (green area) at 100 yards (this circle

is not centered on the point of aim—center of diamond—because a few

hits were significantly low while many hits were slightly high).

Hole representation colors are orange for shots fired on day two,

purple for shots fired on day three and blue is the average center

of two 3-shot groups fired with Norma load. This is all the more

amazing because Mic had removed and reinstalled the scope between

days two and three.

Earl Moore recording point of impact and other information on

a duplicate target. Mic offered to let him shoot many of the

rounds (since it was his rifle), but for some reason Earl

allowed Mic the honor.

We set up targets, chronograph, and rests. Moore and our mutual friend, Rick Corbitt, recorded data. Moore had added large markings on each Mountain Plains target. I could read those markings through the Swarovski 5-30X Z6 scope (certainly not the scope this rifle would wear on safari, but ideal for this testing).

Day 1 goals were to zero the gun, and get the velocity data. After firing two groups, we had the scope properly adjusted. After firing all the loads, we had velocity data. This gave me the information I needed to estimate charge adjustments for the next shooting session.

I calculated the charge needed to launch each bullet closer to the desired velocity, 2,370 fps. I could account for differences in bullet length and weight but variations in bullet toughness (how much each type does or does not obturate in response to the force accelerating it, especially as that force changes) and resulting bullet-to-bore friction, I could not precisely predict the charge corrections needed. Therefore, many of the second-test loads were slower than we wanted and we had to go back for a third session, with corrected charges giving muzzle velocities were acceptably close to 2,370 fps.

Generally, despite a less-than-ideal rest system (for Day 1 testing, we used an “X” style bag, to help minimize recoil punishment), it was obvious most of the tested loads would place 3 shots very close to the minute-of-angle standard with which we are all so familiar, and which is uselessly precise in a rifle intended for hunting dangerous game where shots might not exceed 40 yards! Moreover, when hunting, few hunters can hold good enough to take advantage of such accuracy.

Critical to this test, though, was comparing the zero of every jacketed-bullet round fired in the first and second tests, which suggests the zero did not change enough to matter, despite significant velocity differences. We also tested a 350-grain cast-bullet at about 1,400 fps. It shot dead-center horizontally and only 3-inches low at 100 yards! This all suggests this rifle and chambering are not particularly sensitive to the load used.

On the second and third trips to the range, I used my conventional rear bag and front rest. Moore and Corbitt again kept me lined out, recorded data, and did most of the grunt work. For some reason, they preferred it that way. Several times I offered to let them do the shooting, but, for some reason, they were not interested. For record, I fired one shot with each tested handload and one 3-shot group with each of six factory loads and two 3-shot groups with the Norma factory load.

Handloaders can choose from a wide selection of premium bullets in

both solid and softpoint styles. Some day Mic might consider terminal

performance testing. The components are on hand, it’s just a massive

undertaking.

The Norma load was particularly consistent; it launched the heavy-for-

caliber 450-grain Woodleigh bullet at 2,170 fps, precisely as advertised.

The standard deviation for six shots was 7 fps, and both 3-shot groups

were similar in size. Mic is quite sure this gun and load will shoot

smaller groups than he can manage. This was not the only sub-MOA,

3-shot, 100-yard group fired. More importantly, this load shot

only about 1-3/4-inches lower than the average for the tested

loads using 400- and 410-grain bullets.

This is a good cross-section of all readily available factory loads

made in the past 15 years or so. You don’t have to handload to get

premium performance from a .416 Rigby.

Lessons Learned

The answer to Moore’s initial question had become obvious: Assuming a proper rifle zero, every shot I fired during these three days of shooting would have centered the bullet impact within 2 inches of the intended point of aim at 100 yards. At 50 yards, a more realistic dangerous-game distance, all but one bullet would have hit a 1-1/4-inch circle, centered on the point of aim. The one outlier was the 450-grain Norma factory load. At 100 yards, those shot about 1-3/4-inches low and about 1-1/2-inches right of the basic zero of all other tested bullets and loads.

With the ammunition we tested in this rifle, for normal safari use in the applications where the .416 Rigby is ideal, good advice is: “Zero the rifle dead-center at 100 yards” If you need to buy ammo at your location, it is unlikely you’ll need to shoot up hundreds of dollars of ammo re-zeroing, but just a few rounds instead. Any significant error in shot placement will not result from anything to do with the load or gun.

Source: http://gunsmagazine.com/dangerous-game-good/

The following article from Guns Magazine:

Dangerous-Game Good

The .416 Rigby In Ruger’s 77 Magnum Proves

Remarkably Consistent And Shoots To Point-Of-Aim

With Many Different Loads.

By M. L. McPherson

Earl Moore, whose lifetime dream had been to own a rifle chambered in .416 Rigby was thrilled to get one in the Ruger 77 Magnum. This is essentially a modern equivalent of Rigby’s original rifle. As the last rifle design upon which Bill Ruger had direct oversight, Moore figured this particular combination was a fine tribute to two great gun makers—Rigby and Ruger.

Then an acquaintance of Moore’s went to Africa, and, on the day he was to begin his hunt, discovered his carefully prepared .416 Rigby ammunition had vanished. To continue his hunt, he had to waste an entire day having his guide take him 200 miles to the nearest business with .416 ammo in stock. Forty rounds, $800!

Moore dreams of his own African safari. Therefore, he wondered how the zero of his .416 would vary with different factory loads. If he went to Africa and had to substitute ammunition, would it be necessary to waste valuable time rezeroing his gun, while absorbing the punishment of heavy recoil at the bench, messing up his schedule and perhaps the schedules of his guide and other hunters? Or, could he just go hunting and count on the replacement load to shoot close enough to his tested load so he could make well-centered hits on likely targets at reasonable distances?

He asked if I thought a comparison of zeros with various factory loads and factory-equivalent handloads was worthwhile. Having long realized Murphy’s Law was unreasonably optimistic, I agreed this was a worthwhile study.

So, we set out to obtain factory loads and components for testing. Hornady, Federal, and Norma were kind enough to provide factory ammunition. Alliant provided propellant. Federal provided primers. Hornady provided cases. Various bullet makers provided premium .416 Rigby bullets.

The rest set-up for days two and three allowed Mic to concentrate on

what matters—holding the gun the same way each time and squeezing the

trigger only when things were stable. Elevating the rests allowed Mic

to sit up more squarely behind the gun, which reduced the discomfort

of recoil. Consistent bag technique is key to shooting good groups.

Many who have not priced .416 Rigby ammunition ($7 per round) and components ($4 to 5 for a case, primer, propellant, and bullet) would be dumbfounded to discover just how expensive it is to shoot jacketed bullets from a Rigby. Moore figured out Alliant Reloder 22 was an ideal propellant choice and we knew the Federal 215 was the best primer available for such loads, so we did not have to do much load development work. Still, in this limited testing, we used up the better part of $1,000 worth of factory loads and components.

And, if we had had to purchase the seven boxes of factory ammunition, the 100 cases, the propellant and primers used, and one box of each tested bullet (some come in 10 or 20, and others as 50 per box), we would have exceeded $3,000. Therefore, the generous help of the manufacturers made this project possible.

Although Barnes monolithic bullets worked fine, we tested one other brand of bullet with innovative design features made of monolithic brass. It was worse than useless. By simply loading the magazine with rounds loaded with this bullet we proved that the inclusion of widely spaced circumferential grooves all along the bullet shank left too little of the shank in contact with the case neck for neck tension to hold the bullets in place against recoil. Firing the gun with a normal load generated enough recoil to drive the bullets in the rounds in the magazine back into the case significantly.

Therefore, I can’t too strongly caution against the use of any bullet lacking full or nearly full contact between case neck and bullet shank in this or any similar chambering. The one exception might be a combination where charge compression was sufficient to support the bullet against deeper seating, but how would you ever be completely certain? Better to just avoid such bullets.

This set-up helped minimize the discomfort of shooting more than 50

rounds of .416 Rigby ammunition in one morning. Several things helped:

the “X” bag binds the forearm, 5 pounds of lead shot at the back and,

elevating the gun enough so Mic can sit up behind it, instead of leaning

into it. A scope with ample eye relief is critical, and the Swarovski Z6

worked splendidly. Mic’s friend Rick Corbitt took this posed picture.

He wore shooting glasses for the test.

Details matter. On days two and three of range testing, Mic used his

conventional rests, but with both raised significantly. The tape

on the forearm was a guide to ensure he returned the rifle to the

same location in the front rest before each shot. Normally, for best

groups, Mic would have removed the front sling stud and positioned

the rest farther forward but that was not feasible here because

the stud secures the barrel band of the Ruger 77 Magnum.

Moore loaded all the tested handloads using unfired Hornady cases, Federal 215 primers, and Rl-22 propellant, a fine combination. His initial load development involved considerable preliminary shooting with several bullets. Because data does not exist for every bullet we tested, I used Moore’s preliminary test results to predict charges approximately duplicating factory-load velocity with all tested bullets. Moore loaded three such rounds with each bullet. With ammo in hand, we headed to the local range.

Standard loads fired in this rifle generate significantly more recoil than factory .458 Winchester Magnum loads fired in a gun of the same weight. Regardless of your sensitivity to recoil, bench testing this gun is a significant task. The first day of testing, just to get preliminary velocity data and to zero the scope, I fired 53 rounds. This was about all the fun I wanted to have in one day.

We did several things to reduce pain. I added a 5-pound bag of lead shot between the recoil pad and my shoulder. I have tested dozens of serious loads in the .45-70 Marlin and thereby proved that as long as I consistently position and hold the gun each time I squeeze the trigger, this technique has no effect on zero or accuracy. We also elevated the rests. This allowed me to sit up more squarely so my shoulder could more easily move with the recoil.

I also took aspirin each morning we shot. This is a good idea for me because it loosens my joints but it does promote bruising. I prefer the small amount of local bruising and less pain.

This represents what would have happened if Mic used the same point

of aim when firing all 41 shots during the second and third days

of testing (if the scope had been adjusted to center the weighted-average

impact). This is rather phenomenal, considering it represents 29

handload shots using 19 different bullet types plus the centers of

seven, 3-shot groups fired with six factory loads. Excepting the

Norma load, which uses a significantly heavier bullet, these centers

fell inside a 2-¼-inch circle (green area) at 100 yards (this circle

is not centered on the point of aim—center of diamond—because a few

hits were significantly low while many hits were slightly high).

Hole representation colors are orange for shots fired on day two,

purple for shots fired on day three and blue is the average center

of two 3-shot groups fired with Norma load. This is all the more

amazing because Mic had removed and reinstalled the scope between

days two and three.

Earl Moore recording point of impact and other information on

a duplicate target. Mic offered to let him shoot many of the

rounds (since it was his rifle), but for some reason Earl

allowed Mic the honor.

We set up targets, chronograph, and rests. Moore and our mutual friend, Rick Corbitt, recorded data. Moore had added large markings on each Mountain Plains target. I could read those markings through the Swarovski 5-30X Z6 scope (certainly not the scope this rifle would wear on safari, but ideal for this testing).

Day 1 goals were to zero the gun, and get the velocity data. After firing two groups, we had the scope properly adjusted. After firing all the loads, we had velocity data. This gave me the information I needed to estimate charge adjustments for the next shooting session.

I calculated the charge needed to launch each bullet closer to the desired velocity, 2,370 fps. I could account for differences in bullet length and weight but variations in bullet toughness (how much each type does or does not obturate in response to the force accelerating it, especially as that force changes) and resulting bullet-to-bore friction, I could not precisely predict the charge corrections needed. Therefore, many of the second-test loads were slower than we wanted and we had to go back for a third session, with corrected charges giving muzzle velocities were acceptably close to 2,370 fps.

Generally, despite a less-than-ideal rest system (for Day 1 testing, we used an “X” style bag, to help minimize recoil punishment), it was obvious most of the tested loads would place 3 shots very close to the minute-of-angle standard with which we are all so familiar, and which is uselessly precise in a rifle intended for hunting dangerous game where shots might not exceed 40 yards! Moreover, when hunting, few hunters can hold good enough to take advantage of such accuracy.

Critical to this test, though, was comparing the zero of every jacketed-bullet round fired in the first and second tests, which suggests the zero did not change enough to matter, despite significant velocity differences. We also tested a 350-grain cast-bullet at about 1,400 fps. It shot dead-center horizontally and only 3-inches low at 100 yards! This all suggests this rifle and chambering are not particularly sensitive to the load used.

On the second and third trips to the range, I used my conventional rear bag and front rest. Moore and Corbitt again kept me lined out, recorded data, and did most of the grunt work. For some reason, they preferred it that way. Several times I offered to let them do the shooting, but, for some reason, they were not interested. For record, I fired one shot with each tested handload and one 3-shot group with each of six factory loads and two 3-shot groups with the Norma factory load.

Handloaders can choose from a wide selection of premium bullets in

both solid and softpoint styles. Some day Mic might consider terminal

performance testing. The components are on hand, it’s just a massive

undertaking.

The Norma load was particularly consistent; it launched the heavy-for-

caliber 450-grain Woodleigh bullet at 2,170 fps, precisely as advertised.

The standard deviation for six shots was 7 fps, and both 3-shot groups

were similar in size. Mic is quite sure this gun and load will shoot

smaller groups than he can manage. This was not the only sub-MOA,

3-shot, 100-yard group fired. More importantly, this load shot

only about 1-3/4-inches lower than the average for the tested

loads using 400- and 410-grain bullets.

This is a good cross-section of all readily available factory loads

made in the past 15 years or so. You don’t have to handload to get

premium performance from a .416 Rigby.

Lessons Learned

The answer to Moore’s initial question had become obvious: Assuming a proper rifle zero, every shot I fired during these three days of shooting would have centered the bullet impact within 2 inches of the intended point of aim at 100 yards. At 50 yards, a more realistic dangerous-game distance, all but one bullet would have hit a 1-1/4-inch circle, centered on the point of aim. The one outlier was the 450-grain Norma factory load. At 100 yards, those shot about 1-3/4-inches low and about 1-1/2-inches right of the basic zero of all other tested bullets and loads.

With the ammunition we tested in this rifle, for normal safari use in the applications where the .416 Rigby is ideal, good advice is: “Zero the rifle dead-center at 100 yards” If you need to buy ammo at your location, it is unlikely you’ll need to shoot up hundreds of dollars of ammo re-zeroing, but just a few rounds instead. Any significant error in shot placement will not result from anything to do with the load or gun.

Source: http://gunsmagazine.com/dangerous-game-good/

Last edited by a moderator: