ChrisG

AH elite

- Joined

- Jan 6, 2015

- Messages

- 1,555

- Reaction score

- 2,852

- Location

- Adirondack Park, NY, USA

- Media

- 45

- Articles

- 2

- Member of

- NAHC, NRA, Rocky Mtn. Elk Foundation.

- Hunted

- USA, Canada

So I was at my local gun shop the other day and he had a Marlin 512 on the rack for a steal. Iron sights and a fully rifled 12 gauge barrel. So I bought it. Originally... it looked like this. This is not my picture but it is the same gun. And it is controlled round feed. It just doesn't have the big Mauser extractor... it is a piece of sheet metal instead. A Mauser extractor on this thing would have added another pound to the weight probably

Being that I can never leave well enough alone... I wanted to use it as a basis for a true short range bear hammer. I know in the "slugs for bear" thread that I said I don't like foster slugs... and that is true. But this isn't going to fire foster slugs....

So last night I cut the barrel back to 18.5" and re-crowned it.

I ordered a mass of Magtech 12 Gauge brass hulls and all the correct 11 gauge fiber wads and nitro cards:

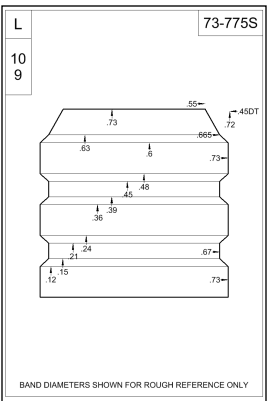

and a 775 grain .732" Accurate Molds Bullet mold that looks like this:

I am looking to load shells like these:

Only they will be huge flat noses with a .55" meplat.

Then the real work begins. The stock will be reshaped to be more of a European rounded forend, a more tapered pistol grip and a new darker finish, then cut new checkering.

In the end what I will have is an 18.5" CRF 12 bore rifle capable of slinging a 775 grain wadcutter to around 1,200 fps for close in Adirondack bear hunting. I think it will be lots of fun! It is sort of a "making a silk purse from a sow's ear" but I thought it would be a fun project nonetheless. Is there anything else I should do while I am at it?

Being that I can never leave well enough alone... I wanted to use it as a basis for a true short range bear hammer. I know in the "slugs for bear" thread that I said I don't like foster slugs... and that is true. But this isn't going to fire foster slugs....

So last night I cut the barrel back to 18.5" and re-crowned it.

I ordered a mass of Magtech 12 Gauge brass hulls and all the correct 11 gauge fiber wads and nitro cards:

and a 775 grain .732" Accurate Molds Bullet mold that looks like this:

I am looking to load shells like these:

Only they will be huge flat noses with a .55" meplat.

Then the real work begins. The stock will be reshaped to be more of a European rounded forend, a more tapered pistol grip and a new darker finish, then cut new checkering.

In the end what I will have is an 18.5" CRF 12 bore rifle capable of slinging a 775 grain wadcutter to around 1,200 fps for close in Adirondack bear hunting. I think it will be lots of fun! It is sort of a "making a silk purse from a sow's ear" but I thought it would be a fun project nonetheless. Is there anything else I should do while I am at it?